Lastly, more tests of precision could possibly be utilized that figure out the material of specific elements in the final volume from the parenteral nourishment admixture. Typically, pharmacy departments do not need the aptitude to routinely carry out chemical analyses which include analyses of dextrose or electrolyte concentrations. Consequently, hospital or institutional laboratories could possibly be termed upon to perform these high quality assurance tests. Having said that, the methods in this sort of laboratories will often be suitable for Organic, not pharmaceutical, techniques. Therefore, their testing methods have to be verified to satisfy the USP specifications stated in the person monograph for that ingredient currently being tested.

Number of Units:- It's recommendable to incubate all units of media fill. In almost any situation the complete documentation of all filled models is necessary. It can be done to pick out broken models ahead of incubation As outlined by plan processing. Although the correct reconciliation of all units is a standard need. It's not acceptable to pick out constructive units right after incubation because the checking reveals defects one example is while in the container closure method.

Monitoring Managed Storage Locations In order that item potency is retained from the company's labeled expiration date, pharmacists should keep an eye on the drug storage parts throughout the pharmacy. Managed temperature storage regions inside the pharmacy (refrigerators, two

Microbiology or Environmental checking shall retain a cumulative summary of all aseptic course of action simulations, like First studies.

Assuring that personnel is capable by means of a documented teaching method to collect, Assess and test samples relevant to aseptic approach simulations, like environmental monitoring samples.

Materials to generally be used while in the DCCA with the planned techniques are accrued and then decontaminated by wiping or spraying the outer surface area with IPA or removing the outer wrap at the sting with the DCCA since the item is launched into your aseptic work spot.

from three get more info consecutive batches progress is noticed only in one unit in next batch than what techniques need to be taken??

Penned treatments need to exist making sure that storage circumstances within the client-care setting are ideal for the CSP-precise storage requirements. Methods include things like day by day monitoring and documentation of drug storage fridges to ensure temperatures concerning two

Shut the dispensed material, affix the weighing tag and transfer the material from the dispensed product storage space.

Through our in depth 60+ years of working experience, we’ve acquired the tricky way that Media Fill testing is often a time consuming bottleneck.

Evaluate GP validation, if media was filled immediately soon after product, and Evaluate them against the particular media filling problems.

Chemotoxic and other hazardous CSPs call for safeguards to keep up the integrity of your CSP and to attenuate the publicity prospective of those products and solutions to read more the setting and also to staff who may well are available connection with them. Exclusive demands related to the packaging, transportation, and dealing with of such brokers include things like the avoidance of accidental exposures or spills and the education of personnel during the occasion of an publicity or spill. Examples of Particular needs of these agents also contain exposure-lowering approaches like the use of Luer lock syringes and connections, syringe caps, the capping of container ports, sealed plastic bags, effects-resistant containers, and cautionary labeling.

The existing discussion of your contamination amount aims at unfavorable detection of contaminated models. A contamination charge of 0.one% will not be tolerated by FDA’s inspectors. Any favourable unit should be examined completely and could be described as a reason behind the failed media fill. FDA’s acceptance of the chance in test benefits (0.1% contamination level) does not signify that an aseptically processed large amount of drug product or service purporting for being sterile may perhaps have just one non-sterile unit for every thousand depend. Based on PIC/S26 the contamination level needs to be Preferably zero but the statistic method refers to ISO 13408-1.

Generally, provides required with the scheduled functions of the shift are geared up and introduced into the buffer or clear space, ideally on one or more movable carts. Materials which might be necessary for again-up or common aid of functions may be saved to the designated shelving from the buffer or cleanse region, but prevent too much accumulation of materials.

Ralph Macchio Then & Now!

Ralph Macchio Then & Now! Heath Ledger Then & Now!

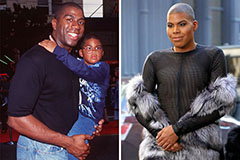

Heath Ledger Then & Now! Earvin Johnson III Then & Now!

Earvin Johnson III Then & Now! Lacey Chabert Then & Now!

Lacey Chabert Then & Now! Ricky Schroder Then & Now!

Ricky Schroder Then & Now!